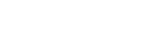

Sugar cane must pass several physical-chemist processes to be transformed into sugar, alcohol and energy.

Let’s see how is done:

Process of fractioning dry sugar in different forms according to customer needs

Juice purification process by means of sedimentation of sludge or impurities.

Increasing the temperature of the sugarcane juice (from room temperature to 102°C) using steam and heating equipment as pre-treatment for clarification.

Transformation of thermal energy of the steam generated in the boilers into electricity using turbogenerators.

Process in which the sugar cane produced in the field is transported to the sugar production Factory.

Production of mineral organic fertilizer from by-products of sugar production and anhydrous alcohol.

Storage of different presentations of sugar in controlled conditions of temperature and humidity.

Sugar production process of high purity from white sugar using more efficient clarification and filtration processes.

The process of removing excess moisture from sugar by placing it in contact with dry and hot air in rotating drying equipment.

Process of separating sugar crystals and molasses using centrifuges.

Formation process of sugar crystals by evaporating water under controlled conditions of temperature and concentration in vacuum equipment.

The process of removing water from sugarcane juice to become cane syrup, using multi-stage evaporation equipment.

Recovery process of sucrose from sludge using vacuum filters.

Transformation of treated water in steam under high pressure and temperature for thermal processes in the Factory and for electric power production.

Sugarcane juice extraction process using mills through mechanical compression.

Process in which the sugar cane produced in the field is cut and lifted.

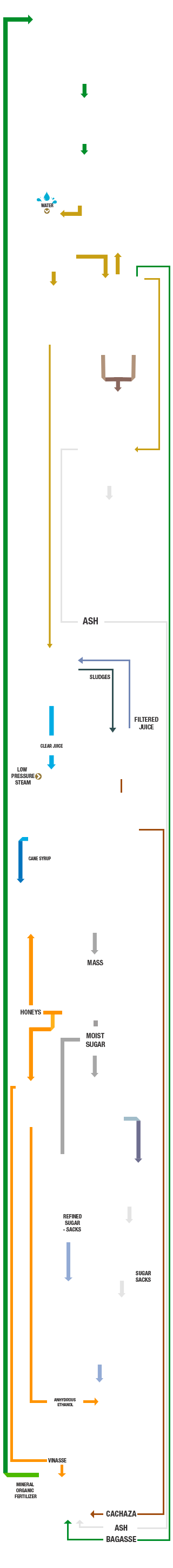

It includes all manual and mechanized farming activities required by sugarcane crops, including the design, adaptation, preparation, planting and raising of plantations until harvest.

Browse and interact with the infographic

Browse and interact with the infographic

Countryside

Harvesting

Sugarcane

transport

Milling

BAGASSE FOR PAPPER

BAGASSE

HIGH PRESSURE

STEAM

Steam

generation

LOW PRESSURE

STEAM

ELECTRIC

POWER

Power

generation

JUICE

WARMING

COAL

WATER

JUICE

EVAPORATION

Juice

clarification

Sludge filtration

Cachaza

Crystallization

Centrifugation

Drying

Sugar

Packaging

Sugar

Refinery

Finished

product warehouse

Ethanol

production

Customers

Composting